- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

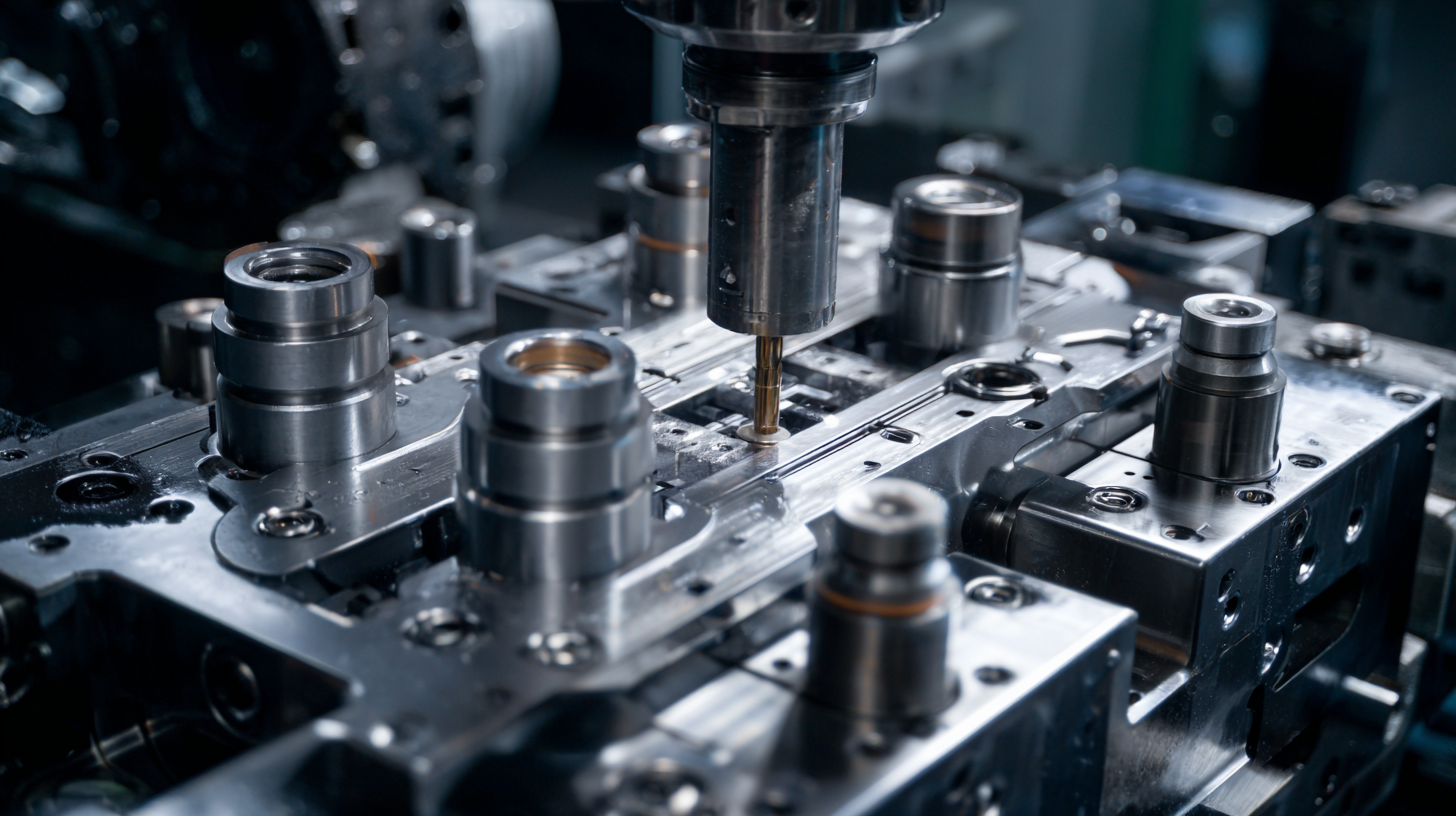

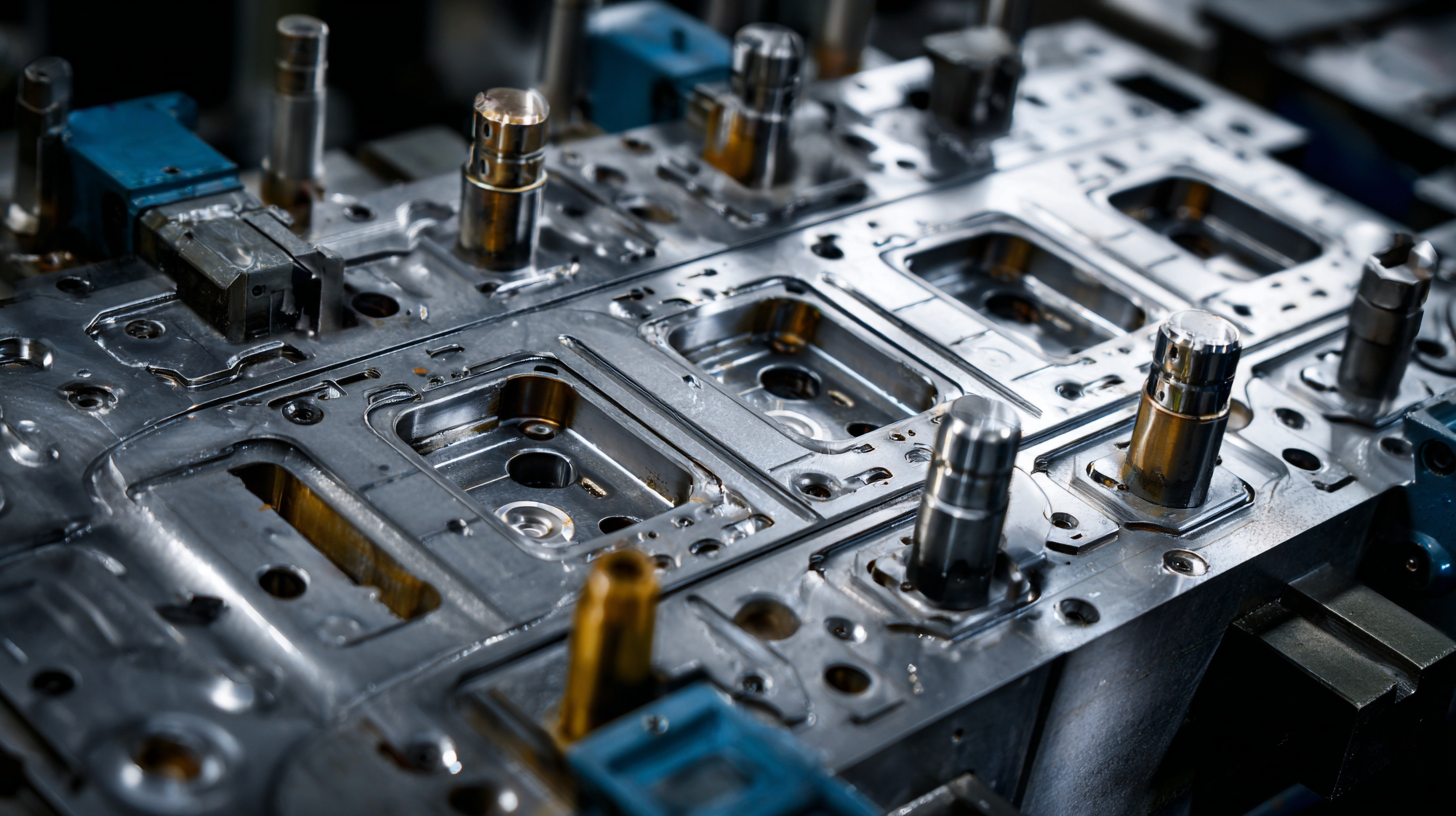

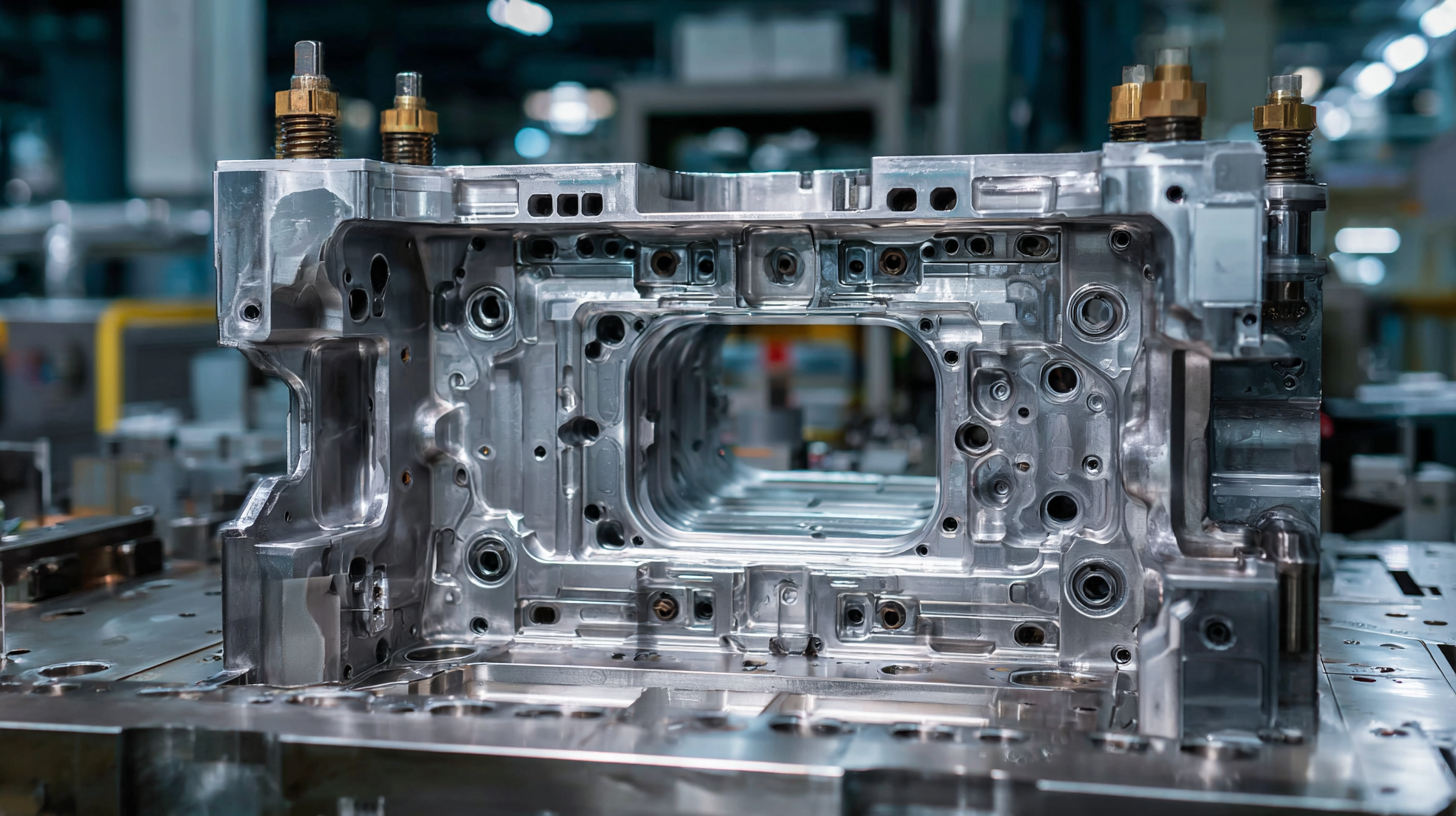

In the competitive landscape of manufacturing, sourcing the best die casting molds has become a critical factor for global buyers aiming to enhance production efficiency and product quality. According to a report by Markets and Markets, the global die casting market is projected to reach USD 7.28 billion by 2026, growing at a CAGR of 4.0% from 2021. This rapid growth underlines the importance of selecting high-quality die casting molds that not only meet specific technical requirements but also align with cost-effectiveness and material compatibility. Understanding the nuances of die casting mold selection—from material types to design intricacies—can significantly impact the success of production lines, making it essential for buyers to equip themselves with a comprehensive checklist to navigate this complex sourcing process.

In the competitive landscape of manufacturing, sourcing the best die casting molds has become a critical factor for global buyers aiming to enhance production efficiency and product quality. According to a report by Markets and Markets, the global die casting market is projected to reach USD 7.28 billion by 2026, growing at a CAGR of 4.0% from 2021. This rapid growth underlines the importance of selecting high-quality die casting molds that not only meet specific technical requirements but also align with cost-effectiveness and material compatibility. Understanding the nuances of die casting mold selection—from material types to design intricacies—can significantly impact the success of production lines, making it essential for buyers to equip themselves with a comprehensive checklist to navigate this complex sourcing process.

The landscape of die casting is poised for transformation by 2025, driven by innovative technologies that promise to enhance efficiency, precision, and sustainability. One of the most notable advancements is the rise of smart manufacturing, which leverages IoT (Internet of Things) and AI-driven analytics. By integrating real-time data into the production process, manufacturers can optimize mold design, reduce cycle times, and significantly cut down on material wastage. This data-driven approach not only streamlines operations but also enhances product quality, catering to the increasing demands of global buyers.

The landscape of die casting is poised for transformation by 2025, driven by innovative technologies that promise to enhance efficiency, precision, and sustainability. One of the most notable advancements is the rise of smart manufacturing, which leverages IoT (Internet of Things) and AI-driven analytics. By integrating real-time data into the production process, manufacturers can optimize mold design, reduce cycle times, and significantly cut down on material wastage. This data-driven approach not only streamlines operations but also enhances product quality, catering to the increasing demands of global buyers.