How to Choose the Best Die Casting Mold for Your Manufacturing Needs

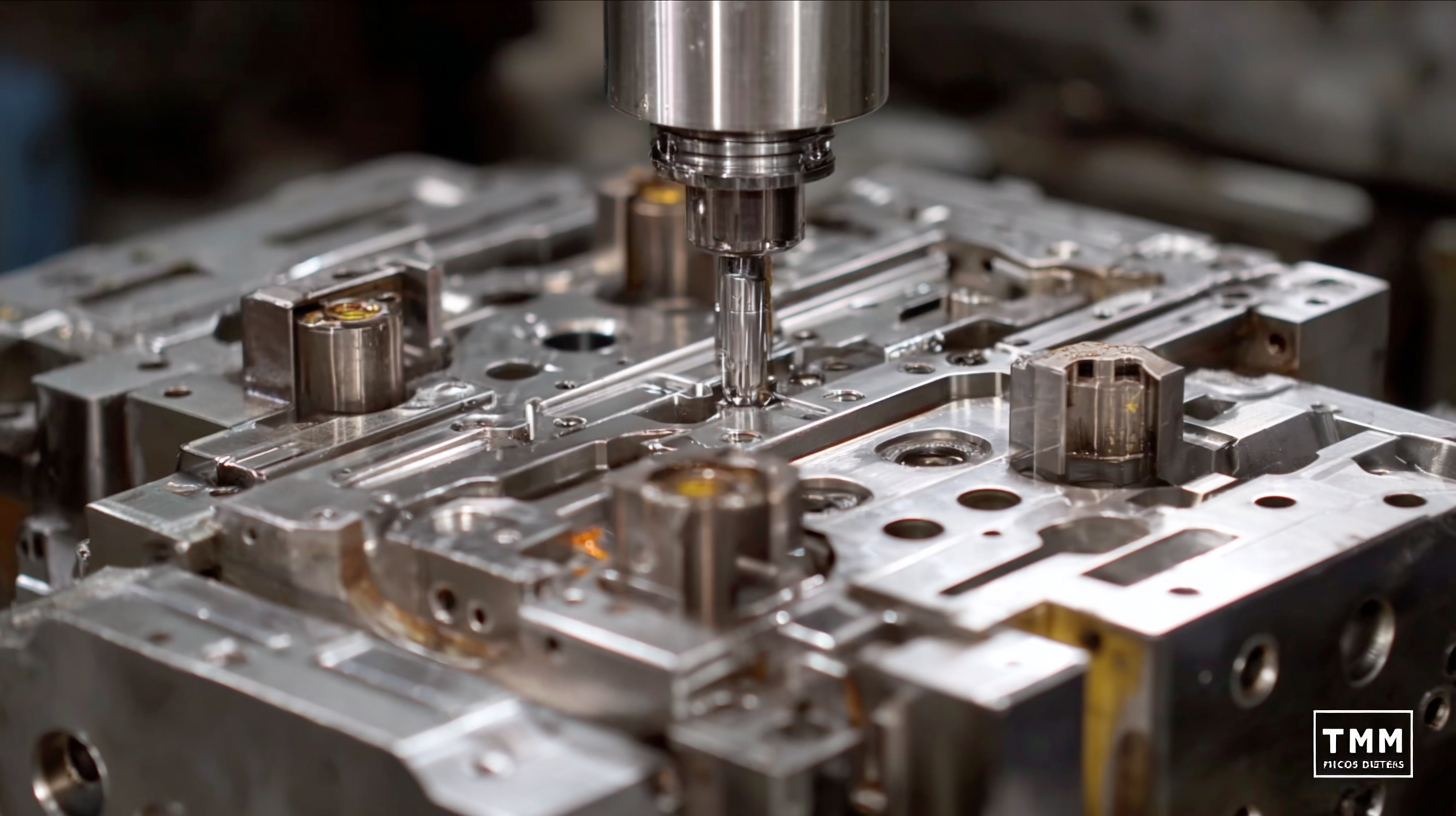

In the ever-evolving landscape of manufacturing, the choice of a Die Casting Mold plays a pivotal role in ensuring product quality, efficiency, and cost-effectiveness. According to a recent report by MarketsandMarkets, the global die casting market is projected to reach USD 90.9 billion by 2026, growing at a CAGR of 5.4% from 2021 to 2026. This significant growth underscores the importance of selecting the right mold for your specific manufacturing needs.

Factors such as material compatibility, thermal conductivity, and design complexity all contribute to the performance and lifecycle of a die casting mold. As industries increasingly seek competitive advantages through improved production methods, understanding the intricacies of die casting molds becomes essential for manufacturers aiming to enhance their operational efficiency and meet consumer demand.

Understanding the Basics of Die Casting Molds: Key Factors to Consider

When choosing the best die casting mold for manufacturing needs, understanding the key factors that influence mold selection is essential. The die casting market is experiencing robust growth, projected to expand from USD 80.23 billion in 2025 to USD 111.77 billion by 2034. This increase highlights the importance of incorporating advanced manufacturing techniques to optimize production efficiency and quality. Key considerations in selecting die casting molds include the alloy material to be used, the complexity of the design, and the expected production volume.

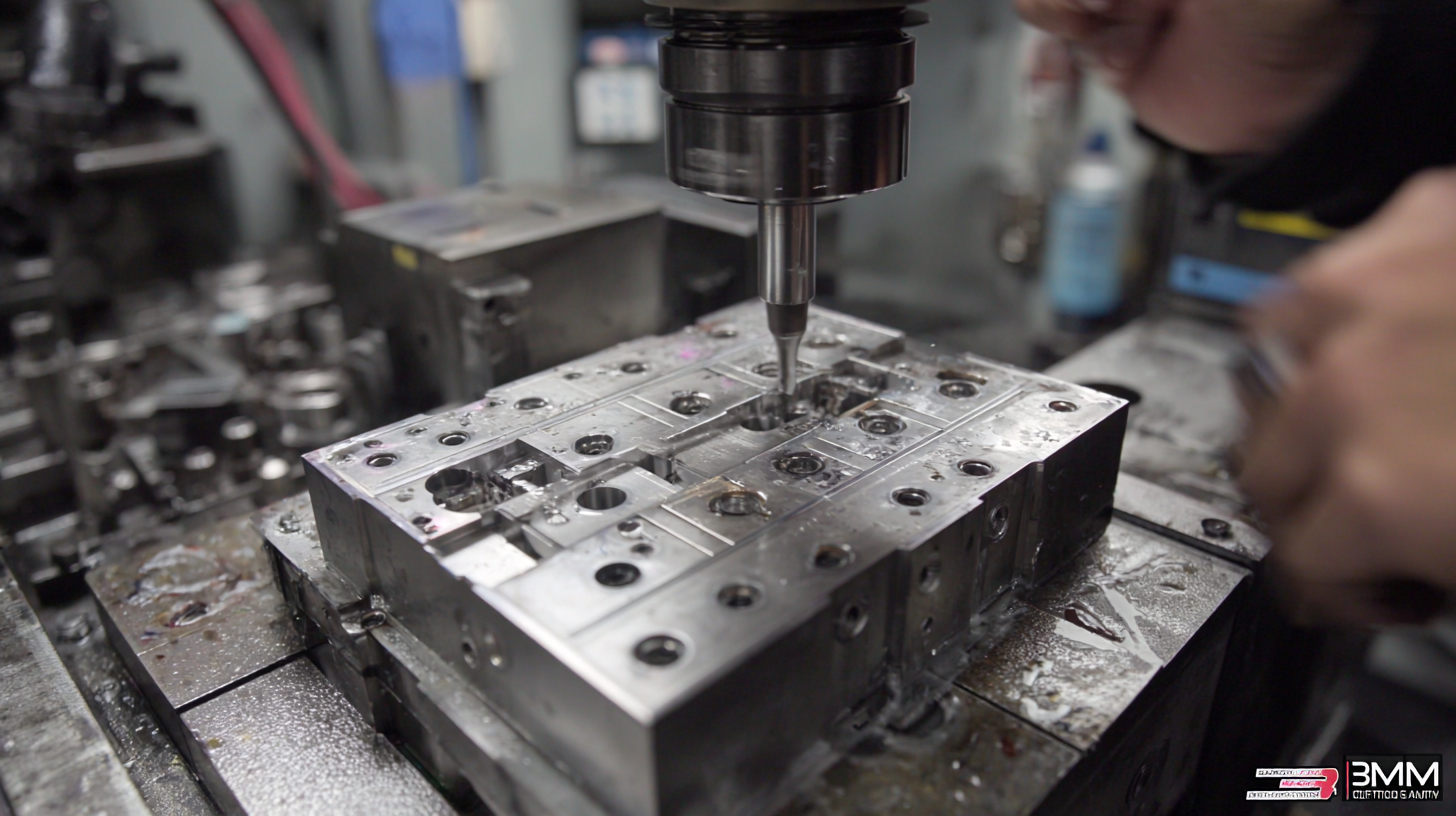

Research into die casting techniques indicates that the choice of alloy significantly affects the final product's properties. For instance, Al-Si alloys are commonly used in die casting due to their advantageous mechanical properties. The incorporation of alloying elements such as copper, magnesium, zinc, and nickel can enhance strength and durability, making them ideal for demanding applications. Additionally, innovations such as lightweight 3D printed sand molds are gaining traction. These structures not only reduce material consumption but also accelerate the casting process, aligning with contemporary industry goals of efficiency and sustainability.

Emerging Trends in Die Casting Technology for 2025 and Beyond

As we look ahead to 2025, the die casting industry is poised for significant advancement, driven by technological innovations and evolving market demands. One emerging trend is the integration of smart technologies into the die casting process.

Manufacturers are increasingly adopting IoT devices and AI-driven analytics to monitor production in real time. This not only enhances operational efficiency but also allows for predictive maintenance of molds, minimizing downtime and improving product quality.

Manufacturers are increasingly adopting IoT devices and AI-driven analytics to monitor production in real time. This not only enhances operational efficiency but also allows for predictive maintenance of molds, minimizing downtime and improving product quality.

Additionally, the push for sustainability is reshaping die casting practices. Companies are exploring eco-friendly materials and energy-efficient processes to reduce their carbon footprint. Innovative recycling methods for aluminum and zinc scrap are also gaining traction, promoting a circular economy within the industry. These developments not only meet regulatory requirements but also appeal to an environmentally conscious consumer base, making sustainability a key consideration for manufacturers looking to remain competitive in the future landscape of die casting.

Top 5 Types of Die Casting Molds: Which One Suits Your Needs?

When selecting the ideal die casting mold for your manufacturing needs, it's crucial to understand the various types available and their specific applications. The top five types include pressure die casting molds, gravity die casting molds, sand casting molds, investment casting molds, and low-pressure die casting molds. Each of these has unique strengths—pressure die casting molds, for instance, excel in producing high-volume components with intricate geometries, ideal for industries requiring precision and uniformity.

The low-pressure die casting market alone was estimated at USD 2.15 billion in 2024, with projections reaching USD 2.98 billion by 2030. This growth highlights an increasing reliance on this method for producing lightweight and strong parts. To enhance mold longevity, innovations such as conformal cooling, which improves temperature regulation during the casting process, are becoming more prevalent. By leveraging advanced materials and technologies, manufacturers can significantly optimize their processes, ensuring higher efficiency and better final product quality. In an era where the demand for superior manufacturing solutions is rising, making an informed choice on die casting molds is paramount.

Top 5 Types of Die Casting Molds

This chart represents the popularity of the top 5 types of die casting molds based on industry preferences. Each type has its unique benefits, making them suitable for various manufacturing needs.

How Digital Tools are Revolutionizing Mold Selection in Manufacturing

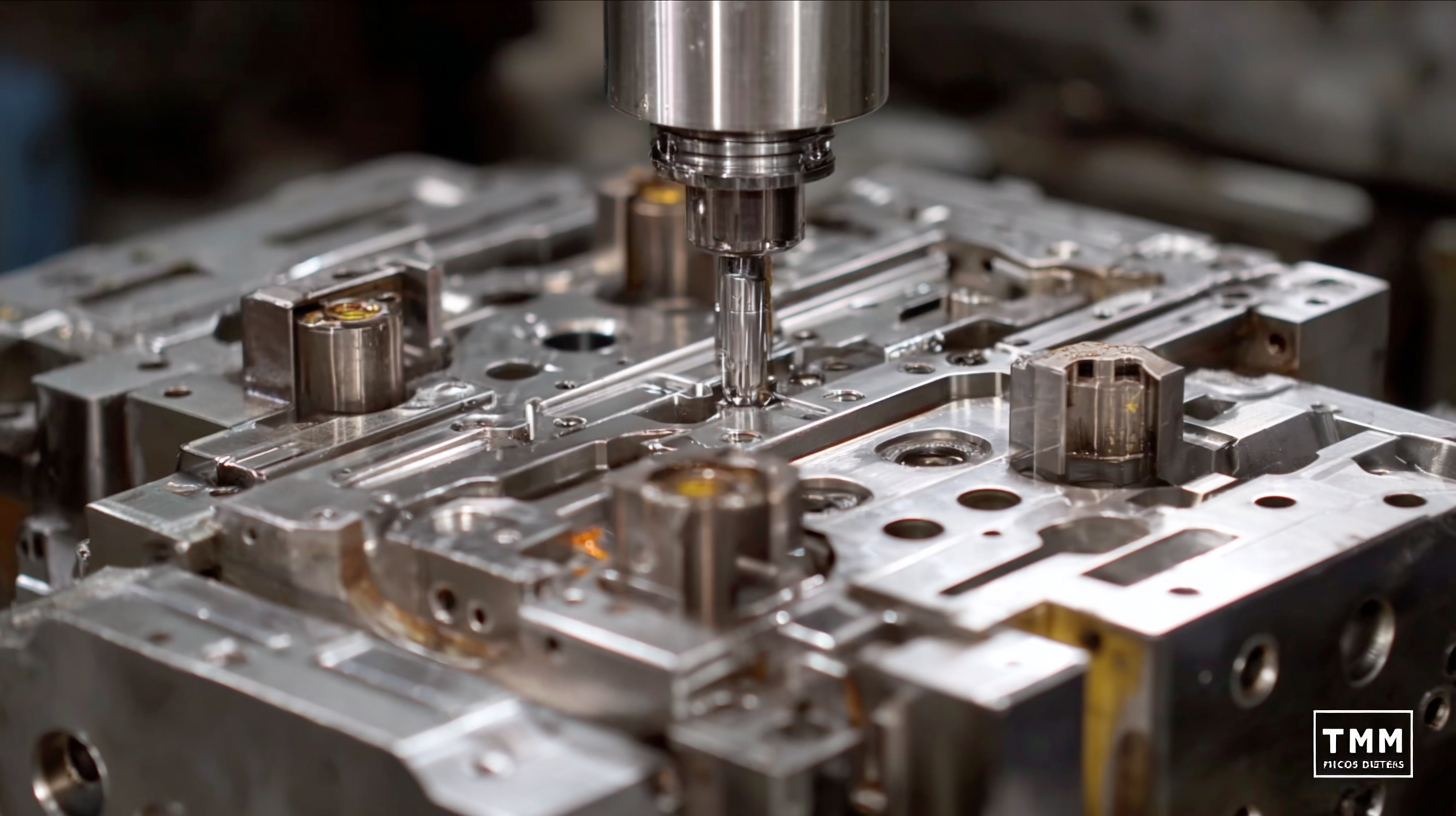

The evolution of digital tools is dramatically transforming the mold selection process in manufacturing, making it more efficient and precise. Advanced simulation software allows engineers to visualize the performance of die casting molds before physical production begins. This capability not only shortens development time but also minimizes costly errors associated with traditional trial-and-error methods. Manufacturers can explore various design iterations quickly, ensuring that the final mold meets all specifications and requirements.

Moreover, data analytics and machine learning are being harnessed to analyze historical mold performance data, which helps in making informed decisions about material selection and design modifications. These insights can lead to optimal mold designs that enhance production efficiency and product quality. By leveraging digital tools, manufacturers can streamline their workflow, reduce lead times, and achieve a higher degree of customization in mold production, ultimately resulting in a competitive edge in the market. As technology continues to advance, the future of mold selection will likely become even more integrated with intelligent systems, further revolutionizing the manufacturing landscape.

How to Choose the Best Die Casting Mold for Your Manufacturing Needs

| Mold Material |

Typical Use Cases |

Advantages |

Disadvantages |

Digital Tool Compatibility |

| Aluminum |

Automotive parts, consumer electronics |

Lightweight, excellent thermal conductivity |

Less durable than steel molds |

High compatibility with CAD and simulation tools |

| Steel |

Heavy machinery, industrial applications |

Highly durable, can withstand high pressure |

Heavier and more expensive |

Compatible with advanced simulation and analysis software |

| Zinc |

Small intricate parts, electronic enclosures |

Good corrosion resistance, economical for high-volume production |

Lower strength compared to aluminum and steel |

Efficient use of digital prototyping tools |

| Magnesium |

Aerospace components, automotive parts |

Very lightweight, high strength-to-weight ratio |

More expensive than other metals |

Integrates well with digitized manufacturing processes |

Cost vs. Quality: Finding the Best Value in Die Casting Molds for 2025

When it comes to selecting die casting molds for manufacturing in 2025, the balance between cost and quality is more crucial than ever. According to a recent report by MarketsandMarkets, the global die casting market is expected to reach $21.19 billion by 2025, driven by increasing demand across industries such as automotive and aerospace. However, it's essential for manufacturers to navigate the complexities of mold selection to ensure they are not compromising on quality for the sake of saving costs.

Data from Technavio highlights that while cheaper molds may reduce short-term expenses, they often result in increased scrap rates and production delays, ultimately driving up costs in the long run. High-quality molds made from durable materials can withstand the rigors of production, reducing wear and tear and leading to significant cost savings over time. In fact, investing in high-quality die casting molds can enhance production efficiency by up to 25% and improve product consistency, allowing manufacturers to seize competitive advantages in increasingly challenging markets. Thus, understanding the long-term implications of mold selection is vital for manufacturers seeking the best value in die casting.

Manufacturers are increasingly adopting

Manufacturers are increasingly adopting